Introduction and Explanation of ABB Touch Screen SP500 Series Panel 800

ABB touch screens mainly include SP500 series and Panel 800 series. The following is a detailed introduction:

SP500 series

Diverse sizes: Available in three screen sizes: 7 inches, 10.2 inches, and 15.6 inches, to meet the installation needs of different devices and environments.

Durable and sturdy: Made of industrial grade plastic/aluminum alloy shell, fully UV coated, front panel protection level IP65, working temperature range -20... 55 ° C, compliant with CE and RoHS standards, suitable for harsh industrial environments.

High definition display: High definition widescreen display, quick startup, simple and intuitive operation interface. Integrated serial port, Ethernet port, and USB interface, can seamlessly integrate with ABB and mainstream PLCs in the market.

Comprehensive functionality: Supports over 200 communication protocols and has strong compatibility. Integrated electronic tag recording, user management, installment payment functions, as well as VNC remote access, trend analysis, alarm and historical recording functions.

Panel 800 series

Version Introduction:

Version 6: Includes standard panel, high-performance panel, black and rugged panel. Standard panels include PP871, PP874, PP877, PP874K, PP877K, etc., suitable for extreme temperature ranges; The high-performance panels PP882 and PP885 have more interface options, faster speeds, and more exquisite displays; Black and sturdy panels are the latest members, such as the "black" marine certification panels PP874M, PP885M, PP885H, and the "sturdy" marine certification panels PP880R, PP885R, PP886H.

Version 5.1: Includes four button panels PP820A, PP826A, PP836A, PP846A, and six touch panels PP815A, PP825A, PP835A, PP845A, PP865A.

Product features:

Easy to use: It is a fully deployable HMI with fully integrated templates and libraries. It can be configured using the Panel Builder tool, which is based on a familiar Microsoft Windows environment and supports multiple languages. Engineering design is fast and simple.

Excellent Display: Vector based high-resolution graphics in TFT/LED displays, with icon based interface navigation and control.

Durable and reliable: Made of a sturdy but lightweight die cast powder coated aluminum shell, the IP65/IP66 front shell can withstand humidity, dust, and harsh environments, with a working temperature range of -10 oC to 60 oC and a maximum humidity of 85%.

Platform openness: Built on an open architecture and technology, based on NET framework, capable of connecting multiple brands of controllers, with multiple connection options for local communication, expansion, remote access, etc.

Partial model introduction:

PP882 and PP885: The display sizes are 12.1 "and 15.4" respectively, supporting high-resolution widescreen TFT/LED backlight, and the touch screen displays 262000 colors. Featuring an enhanced 1.1GHz processor and 1.4GB of application memory, it can support up to 3000 tags and 10 controllers, providing serial ports, two Ethernet ports, and USB interfaces. The front and rear protection levels are IP66/IP20, and the operating temperature ranges from -10 to 50 degrees Celsius.

ABB touch screens have multiple functional functions, mainly including the following aspects:

Intuitive graphical user interface: Provides a simple and intuitive operating interface, using large icons and concise text instructions. Users can operate and control the process by touching the screen, making it more intuitive and user-friendly. Both novice and skilled users can easily get started.

High resolution display: It usually has a high-resolution display screen that can clearly display device status, data trends, alarm information, and other related information, helping operators monitor the system in real time to understand the system situation in a timely manner and make corresponding decisions.

Multiple touch technology support: Generally, capacitive or resistive touch screen technology is used, and some advanced touch screens support multi touch technology, allowing users to operate with multiple fingers and improving operational flexibility.

Customizable interface: Users can customize the touch screen interface according to specific application needs, including layout, graphic elements, buttons, and icons, to meet different operating habits and functional requirements.

Real time data display: It can display sensor data, process variables, production status and other information in real time, allowing operators to have a clear understanding of the system's operating status, facilitating timely detection of problems and adjustments.

Alarm and notification function: It can display and record alarm information, and send notifications to operators, enabling them to take timely measures to deal with problems and ensure the safe and stable operation of the system.

Rich communication interfaces: With multiple communication interfaces, it can communicate with PLC, DCS, SCADA systems, and other control devices to achieve data exchange and control operations, making it easy to integrate into various industrial automation systems.

Complete security features: usually equipped with user permission management, password protection, and security locks to ensure the security of the system and prevent unauthorized operations from causing damage to the system.

Data recording and analysis: It can record data during the operation of the system, facilitate users to query and analyze historical data, help optimize production processes, diagnose faults, and conduct performance evaluations.

Formula function: Some models of ABB touch screens have formula function, which can easily store and manage different production formulas, quickly switch production modes, and improve production efficiency and flexibility.

Recently Posted

-

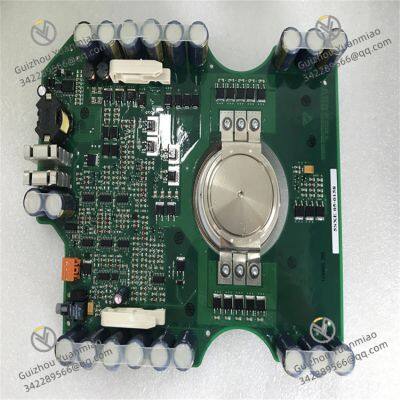

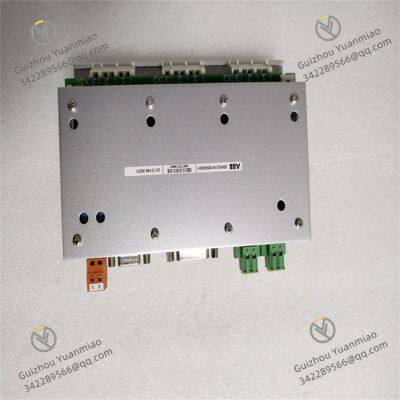

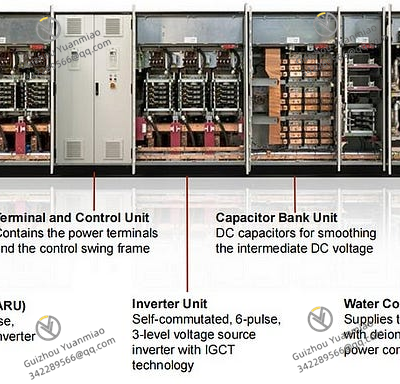

ABB S-073N phase module in the ACS6000 system Medium voltage AC drive

August 19, 2025ABB S-073N phase module in the Medium voltage AC drive ACS 6000, 3–36 MW, up to 3.3 kVABB’s ACS 6000 medium voltage drive provides Read More

Read More -

Introduction to the Complete Series of Foxboro A/I Products

August 19, 2025P0926QS Convert Kit:CC Bay w/Single Post-Mount LCD MonitorP0700AD FBM03 Term Cable (3 Wire), DirectP0926QT Co Read More

Read More -

Foxboro A/I Complete Series

August 19, 2025FBM242 P0916TA I/A Series Channel Isolated 16 Output ModuleP0973FW SMF fiber,duplex cable,LC/LC connectors, 15 Read More

Read More -

Explanation on the Change in the Selection of the 3500/15 AC Power Supply Module

August 16, 2025Explanation on the Change in the Selection of the 3500/15 AC Power Supply ModuleRegarding the 350015 power module, Bentley Shengpi Read More

Read More