Detailed User Manual for ABB PM866 Controller Series and Models

Detailed user manual for ABB PM controller series and models

Detailed user manual for ABB PM controller series and models

Freelance series

PM783F:

Processing capability: Equipped with high-performance processors, capable of handling complex control logic and data processing tasks.

Memory capacity: There is sufficient memory to store programs and data, ensuring the normal operation of the control system.

Communication interface: integrates multiple interfaces such as Ethernet, serial port, and general I/O, supports multiple communication protocols, and facilitates data exchange and communication with other devices and systems.

Design features: Industrial grade design, anti-interference, high reliability, and strong stability, suitable for fields such as factory automation, process control, and power systems.

Other functions: It has a small front panel display that can display status and diagnostic information. Support button lock controller to prevent downloading of applications and firmware, enhancing security. It can connect to S700 I/O modules, with a maximum of eight modules connected to one controller. Third party I/O can be connected through MODBUS ASCII/RTU, IEC 60870-5-101 remote control protocol, or PROFIBUS. The communication speed between the CPU and local S700 I/O modules is fast, and the I/O scanning time can reach 2 milliseconds. Each channel has short circuit and disconnection detection functions.

AC 800M series

PM858K01:

Performance parameters: Equipped with a 33MHz MPC866 processor and 16MB RAM, it has strong ability to handle complex control tasks.

Reliability design: Equipped with redundant Ethernet ports and battery backup real-time clock to ensure high reliability.

Scalability: Modular design, easy to expand to meet application demand growth, supports multiple I/O modules and communication protocols.

Security certification: Obtained ISA Secure certification, meeting strict security standards for industrial control environments.

Technical specifications: There are 2 RJ45 Ethernet ports, 1 RS-232C serial port, and 1 isolated RS-232C serial port, which can connect up to 256 I/O modules and support communication protocols such as PROFIBUS DP, Modbus TCP/IP, Ethernet/IP, etc. The size is 135mm × 186mm × 119mm, and the weight is 1.13kg.

Paper Machine Control System PM800 Series

PM801: Suitable for small and medium-sized paper machines, with basic control functions.

PM802: Suitable for medium and large paper machines, supporting complex control algorithms and optimization management. Adopting a 32-bit ARM Cortex-A9 processor with a clock speed of 1.2GHz, it has 4MB SDRAM (expandable up to 8MB) and 4MB flash memory. It supports communication interfaces such as RS-485, PROFIBUS, Ethernet (including EtherCAT), Foundation fieldbus HSE, etc. The power input is AC220V ± 10% or AC/DC85-265V, the working temperature range is -20 ℃ to+55 ℃, the protection level is IP65, and it supports wall mounted or rack mounted installation.

PM803: Suitable for large paper machines, with advanced fault diagnosis and redundancy functions.

In addition, there are some other ABB PM controller models, such as:

PM901F, PM902F, PM904F: CPU modules belonging to the Freelance series, with different processing capabilities, memory, redundancy, etc., which can meet the performance requirements of controllers in different application scenarios.

YPM106E: It is a servo controller, whose specific functions may be related to motor servo control, used for precise control of parameters such as motor position, speed, and torque.

PM554, PM556, PM564, etc. belong to the logic controller series and have different functions and characteristics, such as differences in digital input and output, communication interfaces, etc., which can be applied to various industrial logic control scenarios. For example, PM556 TP ETH is a programmable logic controller with an Ethernet interface and 6 digital outputs.

The ABB PM858K01 controller is suitable for the following industries:

Industrial automation: It can be used to control robots, conveyors, machining centers and other equipment on the production line, achieve automated control and monitoring of the production process, and improve production efficiency and product quality. For example, in automobile manufacturing factories, robots can be controlled for welding, assembly, and other operations, as well as precise control over the running speed of conveyor belts and material transportation, ensuring smooth production processes.

Power system: plays a role in substation automation, power grid dispatch control, power equipment monitoring, etc., ensuring the stable operation and reliable power supply of the power system. For example, in substations, real-time monitoring and control of switchgear, transformers, etc. can be carried out to achieve remote operation and fault diagnosis, improving the safety and reliability of the power system.

Process control: In process control systems in industries such as chemical, petroleum, and metallurgy, precise control and monitoring of parameters such as temperature, pressure, flow rate, and liquid level can be achieved to ensure the safety and stability of the production process. Taking chemical production as an example, it can accurately control the temperature and pressure of the reaction kettle, ensure that chemical reactions proceed under safe conditions, optimize the production process, and improve product quality and production efficiency.

Intelligent building: used for lighting system control, air conditioning system control, security system control and other aspects of intelligent buildings, to achieve intelligent management of buildings, improve energy utilization efficiency and comfort. For example, by controlling the air conditioning system, the temperature and humidity can be automatically adjusted according to the indoor and outdoor environment and personnel activity, achieving energy-saving operation; The control of the lighting system can automatically turn on and off lights according to light intensity and personnel needs, improving the intelligence level of lighting management.

Recently Posted

-

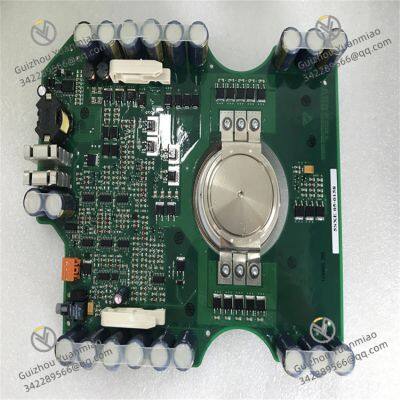

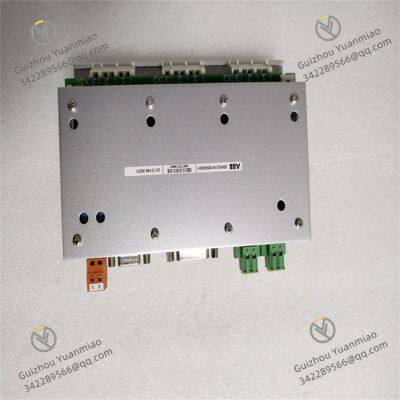

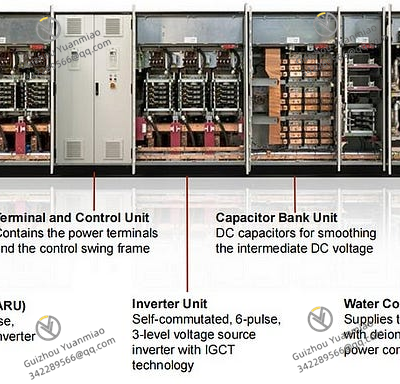

ABB S-073N phase module in the ACS6000 system Medium voltage AC drive

August 19, 2025ABB S-073N phase module in the Medium voltage AC drive ACS 6000, 3–36 MW, up to 3.3 kVABB’s ACS 6000 medium voltage drive provides Read More

Read More -

Introduction to the Complete Series of Foxboro A/I Products

August 19, 2025P0926QS Convert Kit:CC Bay w/Single Post-Mount LCD MonitorP0700AD FBM03 Term Cable (3 Wire), DirectP0926QT Co Read More

Read More -

Foxboro A/I Complete Series

August 19, 2025FBM242 P0916TA I/A Series Channel Isolated 16 Output ModuleP0973FW SMF fiber,duplex cable,LC/LC connectors, 15 Read More

Read More -

Explanation on the Change in the Selection of the 3500/15 AC Power Supply Module

August 16, 2025Explanation on the Change in the Selection of the 3500/15 AC Power Supply ModuleRegarding the 350015 power module, Bentley Shengpi Read More

Read More