Technical Description of Bentley 3500 Series Framework Protocol System

The following is a detailed technical description of the Bentley 3500 system:

System Overview

The Bentley 3500 system is an online monitoring system used for mechanical protection and asset condition monitoring, suitable for various rotating machinery such as turbines, compressors, fans, etc. It can continuously monitor the vibration, displacement, velocity, acceleration, temperature and other parameters of the machine, and can achieve early warning and protection of equipment failures, avoiding equipment damage and production interruption.

System composition

Sensor system: including eddy current sensors (used for displacement, vibration, and key phase measurement), acceleration sensors, seismic velocity sensors, etc. The sensor converts mechanical signals into electrical signals, and the extension cable connects the probe and preamplifier. The preamplifier provides high-frequency power to the probe and processes the signal, generating an output voltage or current signal that varies linearly with the gap.

3500 Framework and Modules:

3500/05 System Framework: It has a 19 inch EIA full-size frame (14 available module slots) and a 12 inch mini frame (7 available module slots), providing installation positions, backplane communication, and power for modules.

3500/15 power module: Half height module, can be installed with one or two, accepts a wide range of input voltages and converts them into the voltage required by other modules, supplies power to the frame, and has redundancy function.

3500/20 Framework Interface Module (RIM): It is the basic interface of the framework, supports proprietary protocols, can be connected to communication processors, provides general functionality for the framework, but is not a critical monitoring path part.

3500/22 Transient Data Interface (TDI): It is the interface between the 3500 monitoring system and the System 1 mechanical management software, used in conjunction with the M-series monitors to collect and transmit steady-state and transient waveform data.

3500/25 Keyphasor Module: A half height, 2-channel monitoring module that obtains input signals from eddy current or magneto resistive probes and provides key signals to the monitor module. A frame can accept up to four key signals.

Working principle

Sensors collect physical quantities from mechanical equipment and convert them into electrical signals, while preamplifiers process and amplify the signals. The single-chip microcontroller of each functional module analyzes, processes, and converts input signals, and compares them with preset alarm values. When the parameters exceed the set point, the system sends an alarm signal and corresponding protective measures can be taken, such as triggering the unit trip. At the same time, the system transmits data to the upper computer or other systems through the communication module for display, storage, and further analysis.

FEATURES

High precision measurement: Using advanced sensors and signal processing technology, it can accurately measure various mechanical parameters and provide accurate data for equipment status assessment.

High reliability: It has self testing and fault-tolerant design, and can be configured with various redundancies such as power redundancy, module redundancy, etc., ensuring stable operation of the system in harsh industrial environments.

Flexible configuration function: Through the 3500 configuration software, the system can be flexibly configured and parameter set according to different equipment and monitoring requirements.

Powerful communication capability: It can seamlessly connect with Bentley System 1 status monitoring and diagnostic analysis software platform, and can also communicate with factory control and automation systems through communication gateway modules to achieve information sharing and integrated management.

performance index

Measurement accuracy: The measurement accuracy of different types of sensors and monitoring modules varies, for example, the accuracy of eddy current displacement sensors can reach ± 0.1% FS (full range).

Response time: The system has a short response time to signals, usually between a few milliseconds to tens of milliseconds, and can capture device status changes in a timely manner.

Alarm settings: Multiple levels of alarm thresholds can be set, including warning, danger, etc. Users can flexibly adjust them according to equipment operation requirements and safety standards.

Communication interface: Supports multiple communication protocols such as RS-232, RS-422, Ethernet, etc., making it easy to connect with other systems.

Recently Posted

-

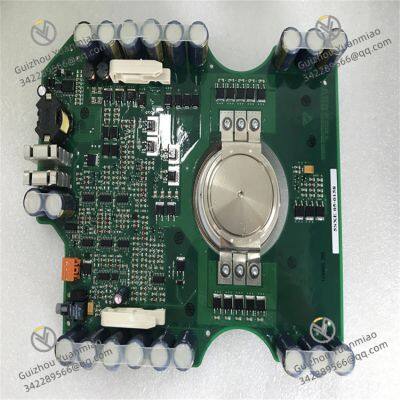

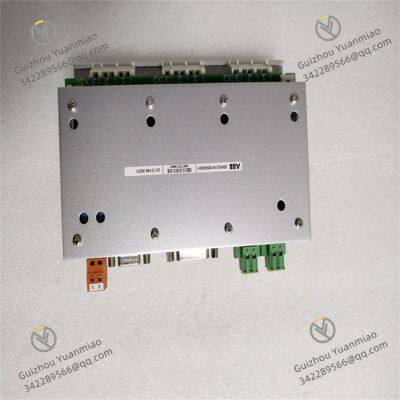

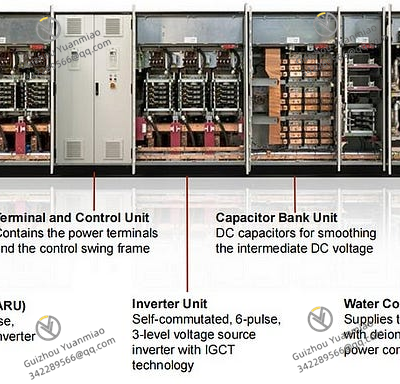

ABB S-073N phase module in the ACS6000 system Medium voltage AC drive

August 19, 2025ABB S-073N phase module in the Medium voltage AC drive ACS 6000, 3–36 MW, up to 3.3 kVABB’s ACS 6000 medium voltage drive provides Read More

Read More -

Introduction to the Complete Series of Foxboro A/I Products

August 19, 2025P0926QS Convert Kit:CC Bay w/Single Post-Mount LCD MonitorP0700AD FBM03 Term Cable (3 Wire), DirectP0926QT Co Read More

Read More -

Foxboro A/I Complete Series

August 19, 2025FBM242 P0916TA I/A Series Channel Isolated 16 Output ModuleP0973FW SMF fiber,duplex cable,LC/LC connectors, 15 Read More

Read More -

Explanation on the Change in the Selection of the 3500/15 AC Power Supply Module

August 16, 2025Explanation on the Change in the Selection of the 3500/15 AC Power Supply ModuleRegarding the 350015 power module, Bentley Shengpi Read More

Read More