Introduction to the full range of ABB robot accessories

Introduction to the full range of ABB robot accessories

As a leader in the field of industrial automation, ABB robots are highly praised for their outstanding performance and reliability. And its full range of accessories is the key to ensuring the efficient and stable operation of robots and expanding their application scenarios. Guizhou Yuanmiao Automation Equipment Co., Ltd., as a professional enterprise deeply engaged in the field of industrial control automation, provides you with comprehensive and high-quality ABB robot parts solutions.

1、 Mechanical transmission accessories

Precision reducer

Harmonic reducer: suitable for ABB robots with loads less than 15kg, such as IRB 120 and other small robots. It has the characteristics of high speed reduction ratio and low backlash, which can achieve extremely precise motion control. The repeated positioning accuracy can reach ± 0.02mm, ensuring that the robot moves delicately and accurately in tasks such as precision assembly and electronic chip picking.

RV reducer: When the robot load is greater than 50kg, such as large industrial robots like IRB 6640, RV reducer is used. It has the characteristics of high rigidity and high torque, and can withstand large external impacts, ensuring stable operation of the robot in heavy-duty operations such as handling and palletizing, and extending the service life of the robot.

Carbon fiber arm kit

This kit is suitable for scenarios that require extremely high speed, such as automotive welding lines. Compared to traditional steel structures, the carbon fiber arm kit reduces weight by 40%, significantly reducing motion inertia and enabling robots to achieve high-speed beats, with a maximum speed of 0.36 seconds per point, significantly improving production efficiency while reducing energy consumption.

2、 Intelligent end execution accessories

QuickChange quick change device

Following the ISO 9409-1 standard interface design, tool switching can be completed in just 0.3 seconds. This feature allows ABB robots to quickly switch between different process tasks, such as in automotive parts processing, where they can quickly switch from drilling tools to milling tools, greatly improving the flexibility of the production line and reducing equipment idle time.

Force Control Module

It has a super high contact force perception capability of 0.1N level, mainly used in scenarios such as the 3C electronics industry that require strict assembly accuracy. For precision assembly of mobile phone glass screens, the force control module can ensure that the pressure applied to the glass screen is uniform and precise during installation, avoiding problems such as glass screen breakage or loose assembly caused by improper pressure, and improving product yield.

3、 Perception and communication accessories

IRC5 control cabinet expansion module

Supporting Profinet and Ethernet/IP dual protocols greatly enhances the networking and communication capabilities of ABB robots with other devices. In large-scale automated factories, robots can achieve high-speed data exchange with devices such as PLCs and sensors through this expansion module, with a network latency of less than 2ms, ensuring the real-time and collaborative performance of the production system.

3D visual positioning kit

Combined with FlexLoader technology, it can accurately identify and locate complex shaped workpieces, increasing the success rate of workpiece grasping to 99.7%. It plays an important role in scenarios such as cargo sorting and disorderly material grabbing in logistics warehousing, effectively solving the problems of low efficiency and high error rate in manual sorting.

4、 Electrical control accessories

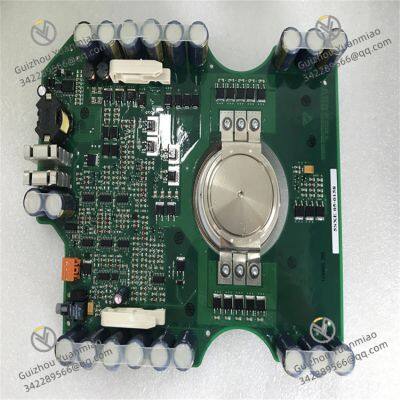

Servo Driver

Provide precise drive control for the motors of each axis of ABB robots, ensuring smooth operation and rapid response of the motors. Different models of robots are equipped with adaptive servo drives, such as the IRB 2600 robot, which is typically paired with servo drives of specific power to meet its motion performance requirements.

Equipped with multiple protection functions such as overcurrent, overvoltage, and overheating, it can effectively prevent damage to robots caused by electrical faults, ensuring equipment and production safety.

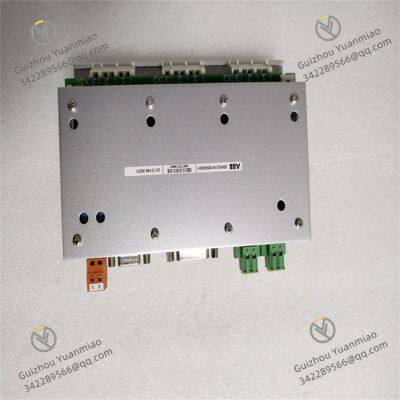

controller

ABB's OmniCore controller uses advanced algorithms and high-performance processors to achieve precise planning and control of complex robot motion trajectories. In robot welding, cutting and other processes, it can ensure that the robot runs accurately according to the preset path, ensuring the quality of processing.

Support multi robot collaborative work, achieve efficient collaboration of multiple ABB robots in the same workspace through synchronous motion control technology, and improve production efficiency and capacity.

5、 Other commonly used accessories

Teaching pendant (FlexPendant)

As a key device for human-computer interaction, the teaching pendant has an intuitive operating interface, allowing operators to manually control the robot's movement, program writing, debugging, and parameter setting.

Some teaching aids, such as the FlexPendant TPU 4, feature high-resolution displays and user-friendly button layouts, making them easy to operate. Even beginners can quickly get started, improving the efficiency of robot programming and debugging.

Cable Assembly

The power line is responsible for providing stable power supply to various components of the robot, ensuring that the robot has sufficient power during operation. It has good conductivity, high temperature resistance, wear resistance and other characteristics to adapt to complex industrial environments.

The encoding line is used to transmit the position and speed signals of the motor, enabling the controller to monitor the real-time motion status of each axis of the robot and achieve precise control. Different models of robots have different specifications and transmission protocols for encoding lines, which require strict matching.

The body cable connects various joints and components of the robot to achieve signal and power transmission, and its flexibility and reliability directly affect the robot's motion flexibility and stability.

Whether in the automotive manufacturing, 3C electronics, or food and pharmaceutical industries, Guizhou Yuanmiao Automation Equipment Co., Ltd. can provide you with a full range of ABB robot accessories that are suitable for your actual needs, helping your enterprise achieve efficient and intelligent production in the wave of industrial automation

Recently Posted

-

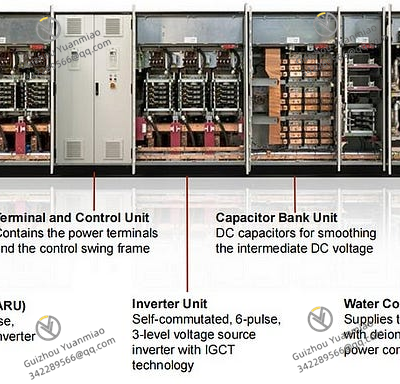

ABB S-073N phase module in the ACS6000 system Medium voltage AC drive

August 19, 2025ABB S-073N phase module in the Medium voltage AC drive ACS 6000, 3–36 MW, up to 3.3 kVABB’s ACS 6000 medium voltage drive provides Read More

Read More -

Introduction to the Complete Series of Foxboro A/I Products

August 19, 2025P0926QS Convert Kit:CC Bay w/Single Post-Mount LCD MonitorP0700AD FBM03 Term Cable (3 Wire), DirectP0926QT Co Read More

Read More -

Foxboro A/I Complete Series

August 19, 2025FBM242 P0916TA I/A Series Channel Isolated 16 Output ModuleP0973FW SMF fiber,duplex cable,LC/LC connectors, 15 Read More

Read More -

Explanation on the Change in the Selection of the 3500/15 AC Power Supply Module

August 16, 2025Explanation on the Change in the Selection of the 3500/15 AC Power Supply ModuleRegarding the 350015 power module, Bentley Shengpi Read More

Read More