Bently Nevada 1900 Series Monitor User Manual

Bently Nevada (now owned by Emerson) brand 1900 series monitor model list * *, used for industrial equipment status monitoring (such as vibration, displacement, speed and other parameter detection of rotating machinery), to ensure safe operation of equipment. The following is a detailed disassembly:

1、 Core Information

-* * Product Series * *: 1900 Monitor Series

-Brand: Bentley (Bently Nevada, the benchmark brand in the field of industrial equipment condition monitoring)

-* * Function * *: As the core unit of the online monitoring system, it collects and processes real-time signals of equipment vibration, shaft displacement, speed, etc. It has functions such as alarm, trend analysis, and data storage, and is commonly used for health management of rotating machinery such as steam turbines, compressors, and fans.

2、 Model Analysis (Taking Typical Models as Examples)

Taking * * BENTLY 1900/65A-01-03-00-00 * * as an example, the meanings of each code segment (refer to Bentley's official technical documentation):

-* * 1900/65A * *: represents the product series and basic functions. "1900" is the series name, and "65A" indicates the signal type that the monitor is compatible with (such as 65A may correspond to eddy current sensor input, used for vibration and shaft displacement monitoring).

-* * 01-01 * *: Usually refers to * * configuration parameters * *, such as the number of monitoring channels (single channel/multi-channel), power supply mode (DC/AC), or whether it supports intrinsic safety explosion-proof (configuration when equipped with safety barriers) corresponding to "01".

-03-00: mostly refers to output and communication parameters. "03" may represent the type of output signal (such as 4-20mA, Modbus protocol), and "00" is the basic communication address/general configuration code.

-* * 00 * *: The ending code is usually * * customized identification * *. If it is "- CN", it is the China regional adaptation version (compliant with domestic electrical standards and certifications).

3、 Product functional differences

The core differences between different models are reflected in their monitoring capabilities and adaptation scenarios

-BENTLY 1900/27: It may be a basic single channel monitor, compatible with small range vibration sensors (such as 2.7mm range), used for vibration monitoring of simple equipment (such as small fans).

-BENTLY 1900/55 *: Suitable for medium range sensors (such as 5.5mm range), supports multi parameter monitoring (vibration+temperature), commonly used in conventional industrial pumps and compressors.

-The model with "65A" is a high-performance model that supports high-precision vibration and shaft displacement monitoring (compatible with eddy current sensors with a range of 6.5mm and above), and can be connected to Bentley 3300 XL series probes for shaft vibration and differential expansion monitoring of key equipment such as steam turbines and generators.

4、 Application scenarios

1. * * Conventional industrial environment * *: such as 1900/27, 1900/55, used for monitoring the vibration intensity of ordinary motors and pumps, triggering local alarms when exceeding the standard.

2. * * Key equipment protection * *: For example, in the 1900/65A series, real-time monitoring of shaft vibration and displacement is carried out on steam turbines and compressors in the petrochemical and power industries. When the vibration amplitude exceeds the set threshold (such as ISO 10816 standard), the linked DCS/PLC system will shut down to prevent equipment damage.

3. Explosion proof scenario: Some models (requiring confirmation of intrinsic safety certification) can be used in hazardous areas such as petrochemical refineries and coal mines to meet explosion-proof requirements (such as IECEx, ATEX certification).

5、 Selection and replacement precautions

1. * * System compatibility * *: The 1900 series needs to be used in conjunction with Bentley sensors (such as 330103 probes) and cables (such as 330130 extension cables). When changing models, the overall system compatibility needs to be confirmed.

2. * * Discontinuation and Replacement * *: Due to Bentley's product iteration (such as gradually promoting the more intelligent 3500 series monitors), some old models (such as 1900/27) may be discontinued, and alternative models (such as 3500/42M, which can replace some functions) need to be queried through official channels.

3. Calibration and Certification: After replacing the monitor, it is necessary to recalibrate the vibration threshold (refer to ISO 10816, API 670 and other standards) and confirm whether it meets the safety certification of the on-site equipment (such as SIL level).

Recently Posted

-

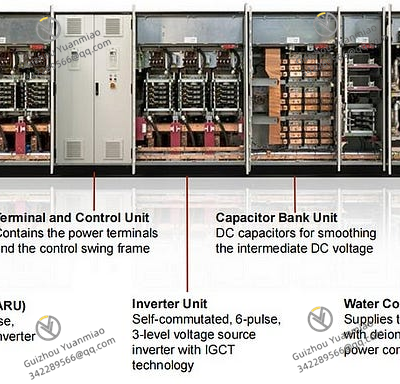

ABB S-073N phase module in the ACS6000 system Medium voltage AC drive

August 19, 2025ABB S-073N phase module in the Medium voltage AC drive ACS 6000, 3–36 MW, up to 3.3 kVABB’s ACS 6000 medium voltage drive provides Read More

Read More -

Introduction to the Complete Series of Foxboro A/I Products

August 19, 2025P0926QS Convert Kit:CC Bay w/Single Post-Mount LCD MonitorP0700AD FBM03 Term Cable (3 Wire), DirectP0926QT Co Read More

Read More -

Foxboro A/I Complete Series

August 19, 2025FBM242 P0916TA I/A Series Channel Isolated 16 Output ModuleP0973FW SMF fiber,duplex cable,LC/LC connectors, 15 Read More

Read More -

Explanation on the Change in the Selection of the 3500/15 AC Power Supply Module

August 16, 2025Explanation on the Change in the Selection of the 3500/15 AC Power Supply ModuleRegarding the 350015 power module, Bentley Shengpi Read More

Read More