Bently Nevada 3300 series vibration monitoring related product models

The model list of Bently Nevada's 3300 series vibration monitoring related products, specifically the Proximitors or system component models that are matched with its eddy current sensors, is used for vibration, displacement, and shaft vibration monitoring scenarios of industrial rotating equipment (such as steam turbines, compressors, fans, etc.) to ensure safe operation of the equipment. The following disassembly key information:

1、 Model Naming Rules (Taking Typical Models as Examples)

Taking BENTLY 330101-00-08-05-02-00 as an example, the meanings of the numbers/letters in each paragraph (refer to Bentley's official technical documentation):

-* * 330101 * *: Represents the product series and belongs to the preamplifier/extension cable assembly of the 3300 XL series eddy current sensor system (different first few digits correspond to different functional modules, such as 330101, which is mostly an extension cable or preamplifier adaptation model).

-* * 00-08 * *: usually corresponds to * * sensor specification parameters * *, such as "08" which may represent the linear range of the sensor (unit: mm, that is, the model is suitable for eddy current sensors with a range of 8mm), and "00" is the basic configuration code.

-05-02: mostly refers to installation and adaptation parameters, such as the thread specification and installation clearance requirements of the sensor corresponding to "05", and the cable length and output signal type (such as whether it is shielded or adapted to intrinsic safety environment) represented by "02".

-* * 00 * *: The ending code is usually * * custom/universal identifier * *, "00" is usually the standard universal version, and if it is "- CN", it may be a customized adaptation model for the Chinese region.

2、 Product Features and Applications

These models are all core components of the Bentley 3300 XL vibration monitoring system, which serve the following purposes:

-Signal conditioning: Combined with eddy current sensors (such as 330103 series probes), the detected physical quantities such as equipment vibration, shaft displacement, and differential expansion are converted into standard electrical signals (such as voltage and current signals).

-* * Equipment protection * *: Real time monitoring of the vibration amplitude and frequency of rotating machinery. When the vibration exceeds the standard, an alarm or shutdown is triggered to prevent equipment damage (such as runaway and bearing wear caused by excessive vibration of the turbine shaft system).

-Typical Application Scenarios: Compressors in the petrochemical industry, steam turbine generators in the power industry, fans in the steel industry, and other critical rotating equipment that require high-precision vibration monitoring.

3、 The practical significance of model differences

The differences between different models are reflected in the adaptation scenarios and parameters:

-Range adaptation: If the model with "08" is compatible with an 8mm range sensor, and if the model with "10" is compatible with a 10mm range, it needs to match the vibration displacement range of the on-site equipment (if the equipment vibration is large, choose a larger range).

-* * Installation environment * *: Some models (including special suffixes) support * * intrinsic safety explosion-proof * * (requiring intrinsically safe certified sensors and safety barriers), which can be used in explosion-proof areas such as petrochemicals and coal mines; Conventional models are suitable for general industrial environments.

-* * Output and Communication * *: Some models are compatible with the * * HART protocol * * (requires additional configuration), enabling digital signal transmission and facilitating integration with DCS and PLC systems; The basic model only outputs analog signals.

4、 Key precautions

1. * * System Compatibility * *: These models need to be used in conjunction with other components of the Bentley 3300 XL series (such as 330103 probes, 3300/16 monitoring modules) and cannot work alone. When selecting, attention should be paid to the overall system compatibility.

2. * * Spare parts management * *: Due to Bentley product updates and iterations (such as the gradual upgrade of the 3300 XL series to a more intelligent system), some old models may be discontinued, and alternative models need to be confirmed through official channels (such as new models that may be compatible with old systems, but parameters must be strictly matched).

3. Calibration and Maintenance: After replacing different types of accessories, the vibration monitoring system needs to be recalibrated (such as adjusting the gain and zero point of the preamplifier) to ensure measurement accuracy, otherwise it may cause false alarms or missed alarms.

Recently Posted

-

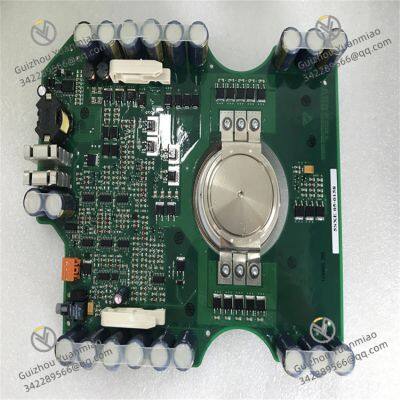

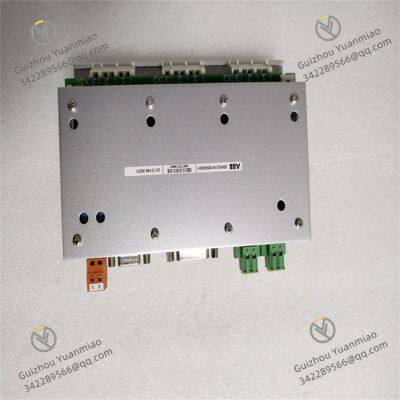

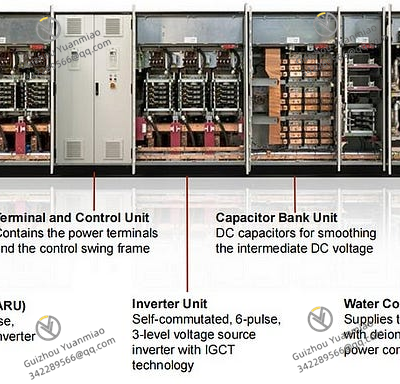

ABB S-073N phase module in the ACS6000 system Medium voltage AC drive

August 19, 2025ABB S-073N phase module in the Medium voltage AC drive ACS 6000, 3–36 MW, up to 3.3 kVABB’s ACS 6000 medium voltage drive provides Read More

Read More -

Introduction to the Complete Series of Foxboro A/I Products

August 19, 2025P0926QS Convert Kit:CC Bay w/Single Post-Mount LCD MonitorP0700AD FBM03 Term Cable (3 Wire), DirectP0926QT Co Read More

Read More -

Foxboro A/I Complete Series

August 19, 2025FBM242 P0916TA I/A Series Channel Isolated 16 Output ModuleP0973FW SMF fiber,duplex cable,LC/LC connectors, 15 Read More

Read More -

Explanation on the Change in the Selection of the 3500/15 AC Power Supply Module

August 16, 2025Explanation on the Change in the Selection of the 3500/15 AC Power Supply ModuleRegarding the 350015 power module, Bentley Shengpi Read More

Read More