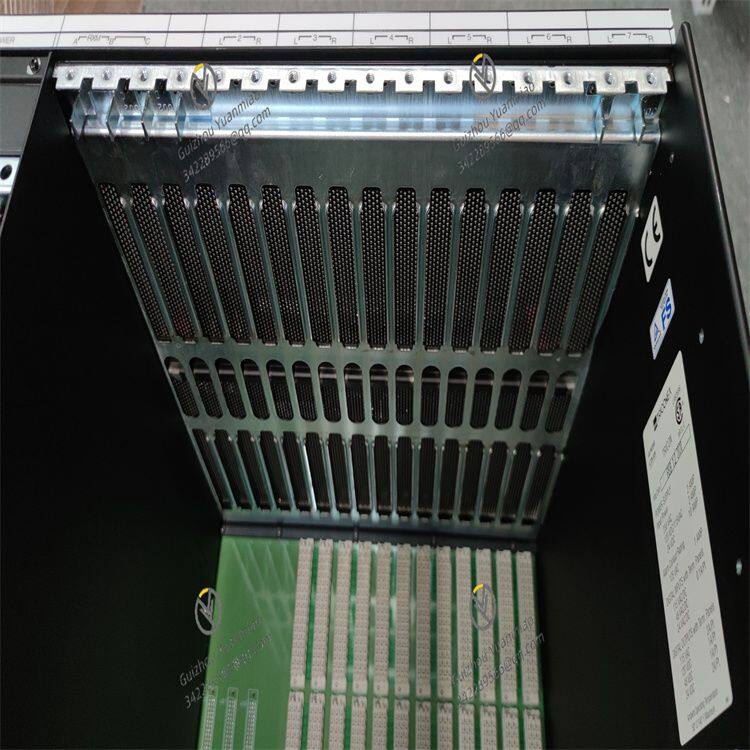

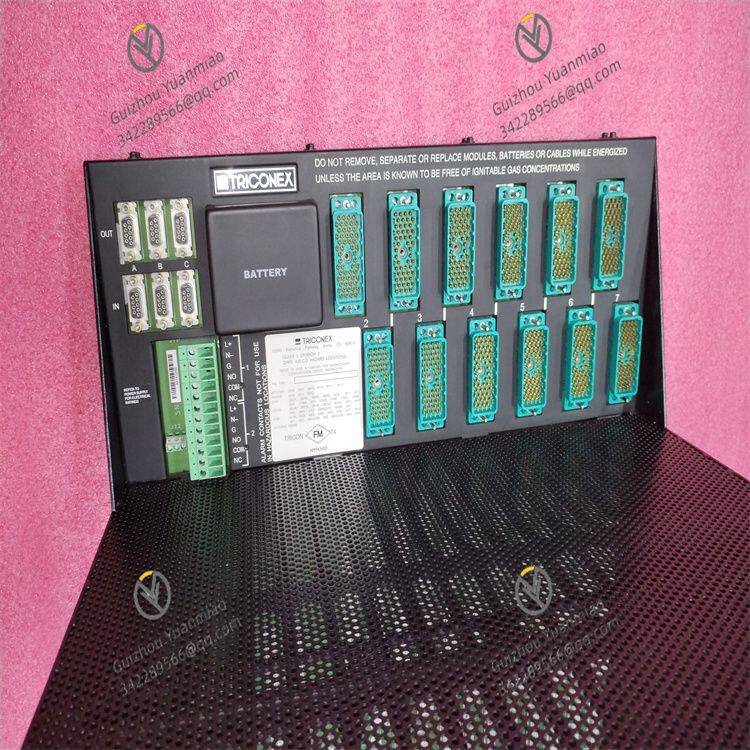

TRICONEX's 8110, 8112, 8111, 8120E full range rack rack user manual

TRICONEX's 8110, 8112, 8111, and 8120E rack series are commonly used hardware devices in industrial automation

control systems. Here are some of their characteristics:

TRICONEX 8110 rack

Structural design: A standard rack mounted structure is usually used, which can be installed in industrial control cabinets for easy integration into the entire control system, providing stable mechanical support and electrical connection environment.

Functional features: Supports the insertion of various modules in the TRICONEX system, such as processor modules, I/O modules, etc., to achieve monitoring and control of industrial processes. Having good electrical performance, it can ensure stable signal transmission and reliable system operation.

Application scenarios: Widely used in various industrial fields, such as petrochemicals, power, metallurgy, etc., suitable for occasions with high reliability requirements for control systems, and can be used to build small to medium-sized automation control systems.

TRICONEX 8112 rack

Structural design: It may have similarities with the 8110 rack in terms of structure, but there may be differences in details such as size and installation holes to adapt to different application requirements and installation environments.

Functional features: It also supports the insertion of multiple modules, which may have certain advantages in module compatibility and scalability, and can better meet the needs of complex industrial control systems for multiple functional modules. For example, it may support more types of I/O modules to adapt to different on-site signal acquisition and control requirements.

Application scenarios: Commonly used in industrial scenarios that require a large number of I/O points and complex control functions, such as large chemical plants, paper production lines, etc., it can provide a reliable control platform for these complex industrial processes.

TRICONEX 8111 rack

Structural design: With a compact structural design, it can provide efficient solutions in limited space. Special layouts and designs may be used to reduce the footprint of the rack while ensuring proper installation and heat dissipation of internal modules.

Functional features: Focusing on meeting some application scenarios with high space requirements, while maintaining the high reliability and performance of the TRICONEX system. Although the structure is compact, it can still support critical control modules and I/O modules, ensuring the functional integrity of the system.

Application scenario: Suitable for industrial environments with limited space, such as offshore platforms, small automated workshops, etc. In these places, it is necessary to ensure the performance of the control system while considering the effective utilization of space.

TRICONEX 8120E rack

Structural design: may have been optimized in terms of structure, using more advanced materials and manufacturing processes, with better mechanical strength and stability. Meanwhile, there may be improvements in heat dissipation design to accommodate higher system loads and harsher industrial environments.

Functional features: Supports the latest control system technology and modules from TRICONEX, with higher processing capabilities and faster communication speeds. For example, it may support new high-speed processor modules that can implement more complex control algorithms and faster real-time responses. In terms of communication, it may have more advanced network interfaces, support multiple industrial communication protocols, and facilitate integration with other systems.

Application scenarios: Mainly used in industrial fields with extremely high performance requirements for control systems, such as aerospace, high-end manufacturing, etc., it can meet the strict requirements of high-precision control, fast data processing, and high reliability in these fields.

These racks typically have high reliability, good compatibility, and scalability, and are an important component of the TRICONEX industrial automation control system. They can be flexibly configured into control systems of various sizes and functions according to different industrial application requirements. However, the specific technical specifications and functional details may vary depending on the product version and manufacturer configuration.

Recently Posted

-

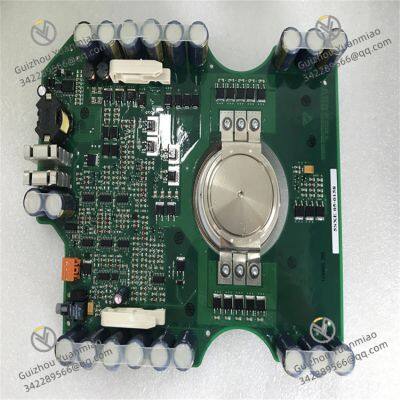

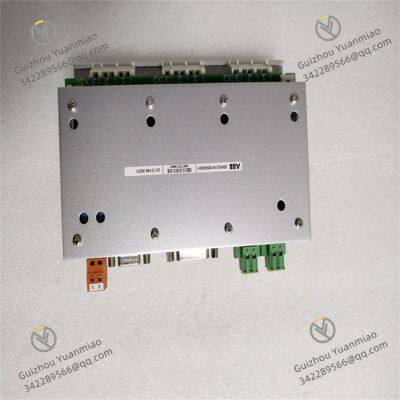

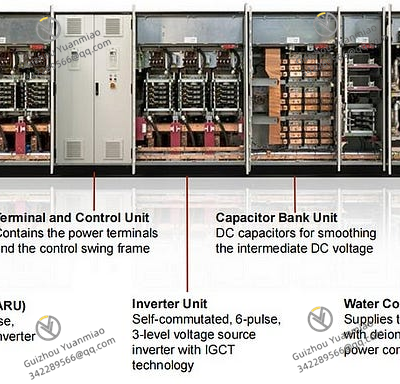

ABB S-073N phase module in the ACS6000 system Medium voltage AC drive

August 19, 2025ABB S-073N phase module in the Medium voltage AC drive ACS 6000, 3–36 MW, up to 3.3 kVABB’s ACS 6000 medium voltage drive provides Read More

Read More -

Introduction to the Complete Series of Foxboro A/I Products

August 19, 2025P0926QS Convert Kit:CC Bay w/Single Post-Mount LCD MonitorP0700AD FBM03 Term Cable (3 Wire), DirectP0926QT Co Read More

Read More -

Foxboro A/I Complete Series

August 19, 2025FBM242 P0916TA I/A Series Channel Isolated 16 Output ModuleP0973FW SMF fiber,duplex cable,LC/LC connectors, 15 Read More

Read More -

Explanation on the Change in the Selection of the 3500/15 AC Power Supply Module

August 16, 2025Explanation on the Change in the Selection of the 3500/15 AC Power Supply ModuleRegarding the 350015 power module, Bentley Shengpi Read More

Read More